- Home

- Operations

- Decommissioning the Greater Dunlin Area

- Current: The Work Streams

We understand that decommissioning can be a complex business. Our approach is to simplify the process as far as possible by focusing on the key drivers whilst adhering to the standards necessary for executing such a large, multi-phase project. This principle has been embedded in the planning and execution of the five main work streams within the Greater Dunlin Area Decommissioning Project.

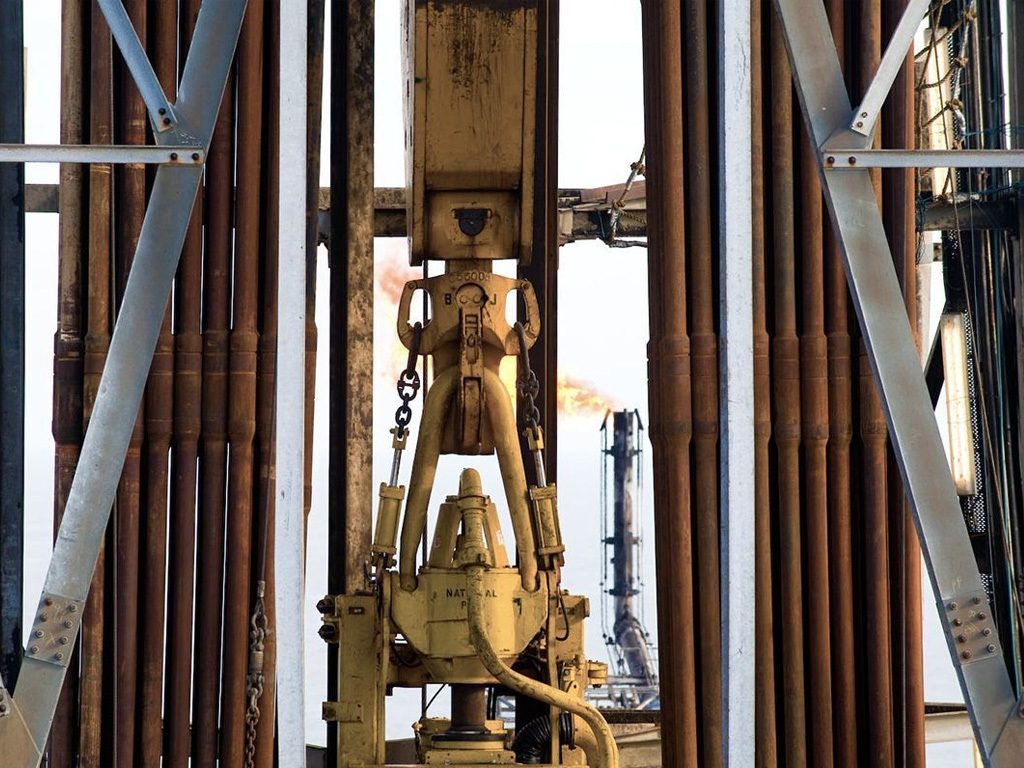

Platform Wells Plug & Abandonment

The plug and abandonment (P&A) of the 45 platform wells on the Dunlin Alpha was a time-critical and significant work scope, involving numerous technical challenges. The Dunlin Alpha wells were plugged and abandoned in accordance with Oil and Gas UK recommended standards and the well activity governed by our Well Integrity Management System (WIMS) and Well Operating Procedures (WOPS) standards and procedures to ensure safe and technically appropriate methodologies were applied.

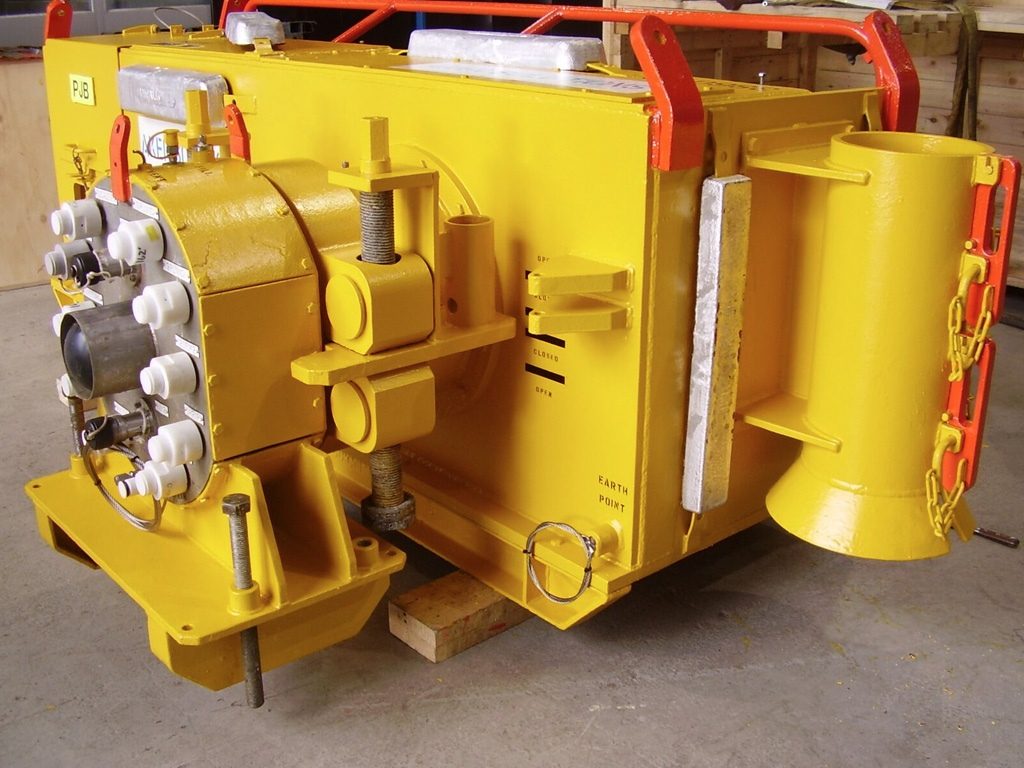

Subsea Wells Plug & Abandonment

The plug and abandonment (P&A) of the 16 Osprey and Merlin subsea wells was executed in a single campaign with a Mobile Offshore Drilling Unit (MODU), Transocean 712. These wells were plugged and abandoned in accordance with Oil and Gas UK recommended standards, with well activity governed by our Well Integrity Management System (WIMS) and Well Operating Procedures (WOPS) standards and procedures. The learnings from the Dunlin Alpha P&A campaign were incorporated into the design of the well programmes, greatly increasing the availability of original equipment manufacturer (OEM) running tools required for well access.

Subsea Infrastructure Decommissioning

The Subsea Infrastructure Decommissioning (SID) campaign to decommission the Osprey and Merlin subsea fields tied back to the Dunlin Alpha installation, and the subsea infrastructure associated with the platform and Concrete Gravity Base Structure was executed in 2018. The SID workstream held a series of comprehensive stakeholder engagement sessions that included completion of the formal Comparative Assessment process, culminating in the approval of the Osprey, Merlin and Dunlin Subsea Decommissioning Programmes in December 2017. The subsea decommissioning scope of work was competitively tendered and Bibby Offshore Limited was awarded the contract. Detailed engineering and planning preparations were followed by offshore decommissioning activities, and thereafter the ecommissioned infrastructure was returned to shore for onward recycling and disposal of recovered materials.

Dunlin Alpha to Cormorant Alpha Oil Export Pipeline (PL5)

The Dunlin Alpha to Cormorant Alpha Oil Export Pipeline (PL5) is a 24” concrete coated trunk pipeline that originally served as an oil export pipeline for comingled production from the Dunlin, Murchison and Thistle platforms respectively. Following decommissioning of the Murchison platform by CNR and Cessation of Production (CoP) from the Greater Dunlin Area fields in 2015, PL5 exported Thistle area production to Cormorant Alpha, where it entered the Brent System ahead of final delivery to Sullom Voe Terminal (SVT).

Use of PL5 as an export pipeline ceased in mid-2019, following Fairfield’s agreement to initially extend the export service for Thistle production, aligned to the Oil & Gas Authority’s Maximising Economic Recovery (MER UK) policy.

Make Safe and Handover

The Make Safe and Handover team was responsible for transitioning the Dunlin Alpha platform from its operational state to a permanent shutdown state with process equipment cleaned, isolated and ultimately left in a safe state for the topsides removal phase. The Dunlin engineering and operations personnel provided in-depth asset knowledge and experience that was critical in avoiding abortive work and optimising the efficiency of work executions. Having fully prepared topsides oil and gas processing vessels and successfully completed a programme of equipment isolation and disconnection in the wellheads area, giving free access for an uninterrupted P&A programme, the team focussed on conductor removal activities which required a multi-disciplinary approach to overcome technical and integrity challenges. Although the COVID-19 pandemic delayed the the cold stack of the Dunlin platform, it was successfully achieved in October 2021 in readiness for the impending removal of the Dunlin topsides.

Topsides Removal and Disposal

Feasibility studies were undertaken to confirm the key technical challenges and execution risks associated with each potential topsides removal methodology. On completion of this evaluation, the work scope for the project Define phase wasinformed by the execution strategy and the outcome of stakeholder consultation and comparative assessment, that determined the key interfaces between infrastructure to be removed and infrastructure planned to be left in situ. During topsides removal offshore execution, the focus was on ensuring the safe and efficient removal of the platform modules in accordance with the agreed removal methodology, sequence and disposal strategy. Following an initial heavy lift campaign involving Heerema Marine Contractors’ SSCV Thialf, the remaining modules were transferred to the deck of the SSCV Sleipnir before it removed Dunlin’s main 11,750-tonne Module Support Frame (MSF) in a single lift in June 2022. The Sleipnir returned to AF Offshore Decom’s Environmental Base at Vats, where more than 95% of the Dunlin topsides will be recycled.